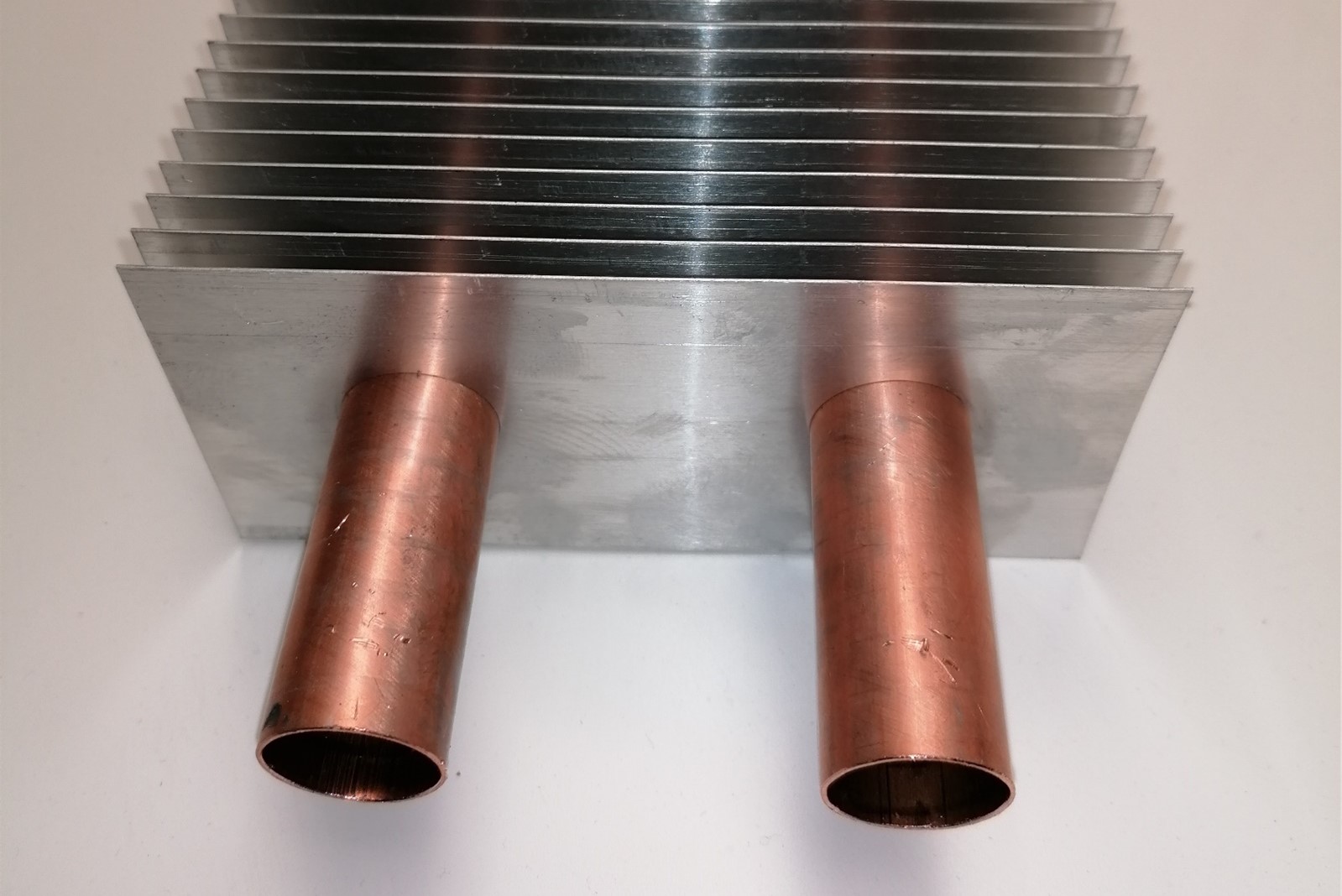

Finrad ® Copper/Aluminium Heating Elements

As well as being used in our trench and perimeter heating casings we also offer our LPHW heating elements separately for installation into builders’ work casings and trench castings.

Also referred to as Cu/Alu coil or baseboard heaters, these in house manufactured elements are available in several sizes with single and twin tube options.

Typical Installations

• Retrofit into steel tube trenches within Churches and

Cathedrals.

• Boats, Caravans and Campervans.

• Under changing room benches.

• Conservatories & Greenhouses.

• Installed into builders’ casings in Schools,

Universities, Hotels and Restaurants.

The Perimeter Heating Company Ltd has taken considerable time and effort to source materials of the highest specification to ensure optimal performance. The fins are manufactured from 0.5mm high thermal conductivity aluminium, mechanically bonded to the copper tube for superior performance over their thinner, closed sided (slide on/slide off) counterparts.

Our customers are not restricted in mounting options either as our elements are open all-round allowing vertical or horizontal mounting of twin pipe systems.

Though consideration should be taken regarding delivery and site handling, our elements can be manufactured to a tube length of up to 2900mm in increments of 25mm (Finned length is 100mm shorter than tube length).

As all products are manufactured to order we are also able to vary the fin pitch at 3mm intervals allowing the spread of heat on specific systems, contact us to discuss your specific requirements. Standard fin pitch is 6mm.

Element support brackets and baffle plates are available to facilitate fitment into pre-cast trenches as well as hanging brackets for installation in builders’ work casings.

Elements are supplied Plain Both Ends (PBE) for braising, compression or speedfit installation. Should site constraints require shortening of the tube, fins can be removed with tin snips and the copper tube shortened as required.

The copper tube is subject to internal pressure exceeding 100 bar during the mechanical expansion process, working pressure should therefore be rated to the jointing method.

Refer to Product Selection for guide outputs and correction factors within TPHC Trench Heating. For outputs within builders’ casing please contact the office to discuss the parameters.

Stated outputs are the result of testing within TPHC trench casing, variations in trench construction will affect output, contact us to discuss any potential issues with design.

Within this brochure you will find cross sections for all standard models for your information. Please call 07803 307 373 to discuss your specific project requirements or forward an enquiry to sales@perimeterheating.com along with as much information as possible for a specification document and/or quotation.

Finrad ® Heating Element Brochure

For professional service, advice and a no obligation quotation for bespoke heating elements please click the buttons below to get in touch today.